From Film to Fabric: The Complete Guide to DTF Printing for Beginners

Introduction

In today’s fast-growing world of custom apparel and merchandise, one printing method is making waves for its versatility and stunning results — DTF printing. Whether you’re a business owner, designer, or hobbyist, understanding how DTF printing works can open doors to new creative and commercial opportunities.

But what exactly is DTF printing, and why are so many creators and print shops switching to it?

This article dives deep into DTF printing basics, explaining the process, key benefits, and how it compares to traditional methods like screen printing and DTG. By the end, you’ll know exactly how DTF printing works, what equipment you need, and how to get the best results for your designs.

What Is DTF Printing?

DTF printing stands for Direct-to-Film printing — a modern digital printing method that allows you to print designs on a special film and then transfer them onto fabrics or other materials using heat and pressure.

Unlike traditional printing methods that print directly onto fabric (like DTG), DTF uses a transfer process — you print the design on a film, coat it with adhesive powder, cure it, and then heat press it onto the final surface.

This simple yet powerful approach gives you:

- Bright, durable prints

- Compatibility with a wide range of materials

- Lower production costs

- Faster turnaround times

It’s no wonder that DTF printing is becoming a top choice for small businesses, print-on-demand services, and creative studios.

Why DTF Printing Is Gaining Popularity

DTF printing offers several advantages that make it stand out from traditional printing techniques. Here’s why it’s becoming a go-to option for professionals and beginners alike:

1. Works on Almost Any Fabric

From cotton and polyester to blends and leather, DTF printing isn’t limited by material. This flexibility gives creators endless opportunities.

2. Long-Lasting and Vibrant Prints

DTF prints resist cracking, peeling, and fading — even after multiple washes. The colors remain vibrant and soft to the touch.

3. Cost-Effective for Small Runs

Unlike screen printing, which requires setup costs, DTF can handle small batches or one-off custom orders without high overhead.

4. Easy to Learn and Scale

With minimal training and the right equipment, anyone can start a DTF printing business or add it to an existing operation.

How DTF Printing Works: Step-by-Step Process

Let’s break down the DTF printing process in simple, practical steps.

Step 1: Design Creation

Everything begins with your design. Use design software like Adobe Illustrator, CorelDRAW, or Photoshop to prepare your artwork.

- Set the background to transparent.

- Use CMYK color mode for accurate print colors.

- Make sure resolution is high (at least 300 DPI).

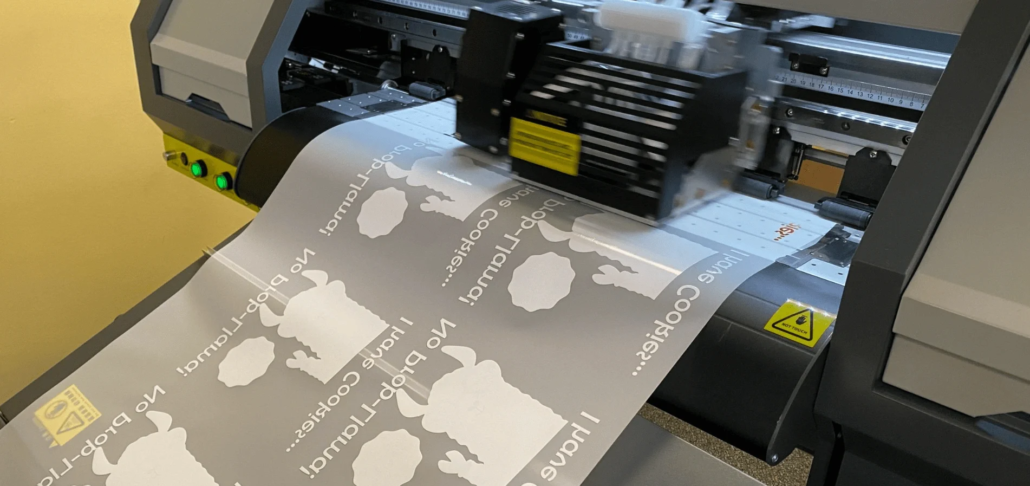

Step 2: Printing on PET Film

Your DTF printer prints the design in two layers:

- First layer: White ink (forms the base layer).

- Second layer: Colored inks printed on top.

This printing happens on PET film (Polyethylene Terephthalate), which has a special coating for ink adhesion.

Step 3: Applying Adhesive Powder

After printing, a hot-melt adhesive powder is applied to the wet ink.

The powder helps the design bond securely to the fabric later. Excess powder is carefully removed.

Step 4: Curing the Film

Next, the printed film with adhesive powder is heated or cured.

You can use a curing oven, heat press, or even a heat gun. The goal is to melt the adhesive powder without damaging the design.

Step 5: Heat Press Transfer

Once cured, the film is placed on the fabric and pressed at around 160–170°C for 15–20 seconds.

The heat and pressure activate the adhesive, transferring the design onto the fabric.

Step 6: Cold Peel

After pressing, allow the film to cool completely before peeling it off. This ensures a clean, durable transfer.

Step 7: Finishing Press

Finally, give the print a second short press to improve smoothness, color vibrancy, and wash durability.

DTF vs. DTG vs. Screen Printing: What’s the Difference?

To understand DTF’s value, let’s compare it with two popular methods — Direct-to-Garment (DTG) and Screen Printing.

| Feature | DTF Printing | DTG Printing | Screen Printing |

| Material Compatibility | Works on cotton, polyester, blends, leather | Works best on cotton | Limited to certain fabrics |

| Setup Cost | Low | Moderate | High |

| Print Durability | Very durable | Good | Excellent |

| Print Feel | Soft and smooth | Very soft | Slightly raised |

| Small Batch Efficiency | Excellent | Good | Poor |

| Color Vibrancy | Very high | High | High |

| Learning Curve | Easy | Moderate | Steep |

Verdict: DTF combines the best of both worlds — high-quality prints, material flexibility, and low production cost.

Essential Equipment for DTF Printing

Starting with DTF printing doesn’t require a massive setup. Here’s what you’ll need:

- DTF Printer – Specialized printers with dual white and CMYK ink channels.

- PET Films – Transparent or matte-coated films for ink transfer.

- DTF Inks – High-quality pigment inks specifically for DTF printing.

- Adhesive Powder – Hot-melt adhesive to bond the design to fabric.

- Curing Oven or Heat Press – For melting adhesive and transferring prints.

- Design Software – Tools like Photoshop or CorelDRAW to prepare artwork.

- Heat Press Machine – For applying heat and pressure during the transfer process.

Pro Tip: Start small — invest in a mid-range DTF printer and upgrade as your orders grow.

Tips for Getting the Best DTF Print Quality

DTF printing is relatively simple, but a few best practices can elevate your results:

1. Use High-Resolution Designs

Low-quality images lead to blurry or pixelated prints. Always use designs with at least 300 DPI resolution.

2. Maintain Proper Printer Settings

Regularly calibrate your printer for accurate color and ink distribution.

3. Handle Adhesive Powder Carefully

Too much powder can cause uneven prints, while too little may reduce adhesion. Find the right balance.

4. Keep Films and Fabric Clean

Dust or oil can affect print quality. Always handle with clean hands and store films properly.

5. Control Temperature & Time

Follow the manufacturer’s heat press guidelines — overheating can dull colors or damage fabrics.

Common DTF Printing Problems (and How to Fix Them)

Even experienced users face occasional challenges. Here’s how to solve the most common issues:

| Problem | Cause | Solution |

| Colors not vibrant | Incorrect color settings or low ink quality | Use ICC profiles and premium DTF inks |

| Print not sticking properly | Uneven adhesive powder or low heat | Reapply powder evenly and increase press temperature |

| Film peeling issues | Peeled while hot | Wait for a full cold peel |

| White spots on print | Excess adhesive powder | Tap off extra powder before curing |

Applications of DTF Printing

DTF printing’s versatility allows it to be used across various industries. Common applications include:

- Custom T-shirts and Hoodies

- Sportswear and Jerseys

- Tote Bags and Caps

- Uniforms and Workwear

- Home Décor (Cushion Covers, Curtains, etc.)

- Brand Merchandise

Its ability to print intricate designs and gradients makes DTF ideal for both mass production and personalized custom orders.

DTF Printing for Small Businesses and Creators

If you’re running a small print shop, e-commerce store, or creative studio, DTF can be a game-changer. Here’s why:

- Low startup cost: Perfect for entrepreneurs just starting out.

- High profit margins: Custom apparel and prints have excellent ROI.

- Scalability: Start small, grow as demand increases.

- On-demand printing: No need for large inventory — print as you go.

Creators and small brands are leveraging DTF to launch unique fashion lines, expand services, and fulfill custom client requests without large upfront costs.

Frequently Asked Questions

1. Is DTF printing better than sublimation?

Yes, in many cases. DTF works on more materials, while sublimation is limited to polyester or coated surfaces.

2. How long do DTF prints last?

With proper washing and care, DTF prints can last for 50+ washes without significant fading or cracking.

3. Can I use a regular printer for DTF printing?

No, you’ll need a specialized DTF printer that supports white ink and uses pigment-based DTF inks.

4. Does DTF printing feel rough on fabric?

No. When done correctly, DTF prints have a soft, flexible feel that blends seamlessly with the fabric.

5. What fabrics are not suitable for DTF?

While DTF works on most fabrics, extremely textured or heat-sensitive materials (like some nylons) may not yield the best results.

Conclusion

DTF printing is reshaping the custom printing landscape — offering high-quality, durable, and flexible solutions for both businesses and creators.

Its simple workflow, wide fabric compatibility, and cost efficiency make it a standout choice in today’s print industry.

At Deepak Printers, we take pride in bringing this innovative technology to life through our best printing services.

With years of expertise, advanced printing equipment, and a dedication to precision, we help individuals and brands transform their creative ideas into vibrant, long-lasting prints.

Whether you need DTF printing for apparel, custom merchandise, or commercial printing solutions, Deepak Printers ensures every project meets the highest standards of quality and craftsmanship.

So, if you’re ready to explore the future of printing — start with Deepak Printers, where innovation meets excellence. Let’s make your designs stand out with color, clarity, and confidence!